Premium Performance by Design

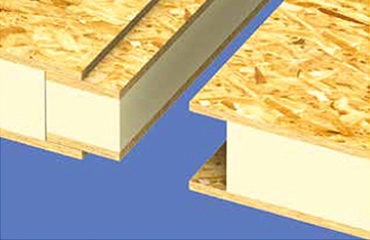

Kingspan TEK™ is the UKs leading manufacturer of premium, high-performance insulation products and building systems. Their Structural Insulated Panels (SIPs) are an advanced building solution, combining insultation sandwiched between two 15mm boards - typically orientated strand board (OSB) - to delivery superior thermal performance, airtightness, and build efficiency.

While there are many SIPs systems on the market, Thomas Carter, as a Kingspan TEK Delivery Partner, supplies and installs the industry-leading Kingspan TEK SIPs building system, featuring high performance, fibre-free rigid thermoset urethane insulation as the core, autohesively bonded between OSB/3 boards. This highly controlled manufacturing process ensures exceptional reliability and superior performance, far exceeding the 'secondary adhesion' methods often used in lower-quality panels.

The result is a building system that is faster to construct, more energy-efficient and built to last - delivering premium quality and precision to our clients.

Download the Kingspan TEK™ Building System Brochures

Comprehensive technical information and specifications for the Kingspan TEK™ Building System SIPs products can be found on the Kingspan Insulation website

VIEW HEREWhy Kingspan TEK™ Building System

Thermal Performance: Fibre-free rigid polyurethane insulation minimises thermal bridging.

Airtightness: Exceptional, consistent sealing reduces heat loss and draughts.

Superior Energy Effiency: Improved insulation can significantly reduce heating costs.

Speed: Off-site manufactured panels enable rapid on-site assembly, reducing build time and disruption.

Quality Control: CNC-cut panels produced in a controlled factory environment ensure precision and consistency.

Lightweight Construction: Reduced structural load can lower foundation requirements.

Strength: 15mm OSB/3 panels provide robust structural performance, suitable for buildings up to four storeys.

Space Optimisation: Slim wall profiles maximise internal, useable floor space.

Sustainable: Lower embodied carbon construction. PEFC-certified timber components. A responsible, future-focused building solution with responsible and proven supply chain audits.

Adaptability, Versatility and Diversity

The SIP system leaves ample scope for individual design. The panels are pre–cut to match a project’s engineering and design specifications and a complete kit is delivered to site ready for erection.

This system can be used to create buildings up to 4 storeys in height unsuported, the panels being used to create the walls (load-bearing and non–load-bearing) and roofs of a complete building.

The panels are lightweight compared with brick and block and therefore are ideal for use where heavy construction may not be possible.

As with all construction methods including traditional masonry, a long lasting external weather proofing is a necessary part of walls and roofs constructed using the SIP system. A variety of external finishes can be used from traditional brickwork to a huge choice of different cladding designs, styles and materials, wood finishes and renders. All are useable with SIP construction.

The SIP roof and wall elements can be used individually with other non–SIP system components. For example, SIP panels can be used as a wall system in conjunction with a timber rafter roof or with steel frame or part of a brick and block structure.

In most cases SIPs are ideal for extensions, conversions or additions to existing buildings regardless of their structure type.

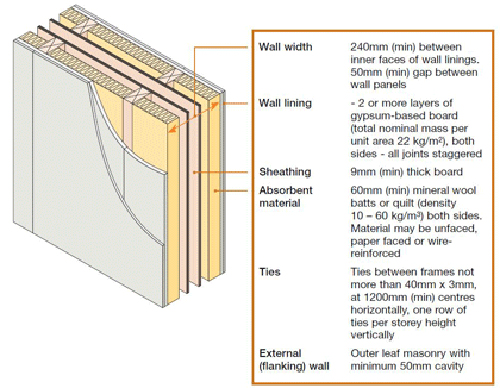

Adding Robust Detail for Party Walls

View the new robust details approved with the SIP building system in terms of acoustic transfer between dwellings for wall types E-WT-1 and E-WT-2. E-WT-2 has now been proven with cavity fill insulation to reduce the impact of thermal bypass in the party wall cavity to a zero value in your SAP calculations, whilst still complying with robust detail.